With our non-destructive testing approach, we provide comprehensive reports and actionable insights that empower you to make informed decisions regarding maintenance, repairs, or new construction projects. Trust Accu-Test for reliable, efficient, and precise concrete evaluation using Ultrasound Pulse Velocity.

Ultrasound Pulse Velocity (UPV) is a versatile technique that can be applied to evaluate concrete materials in various ways:

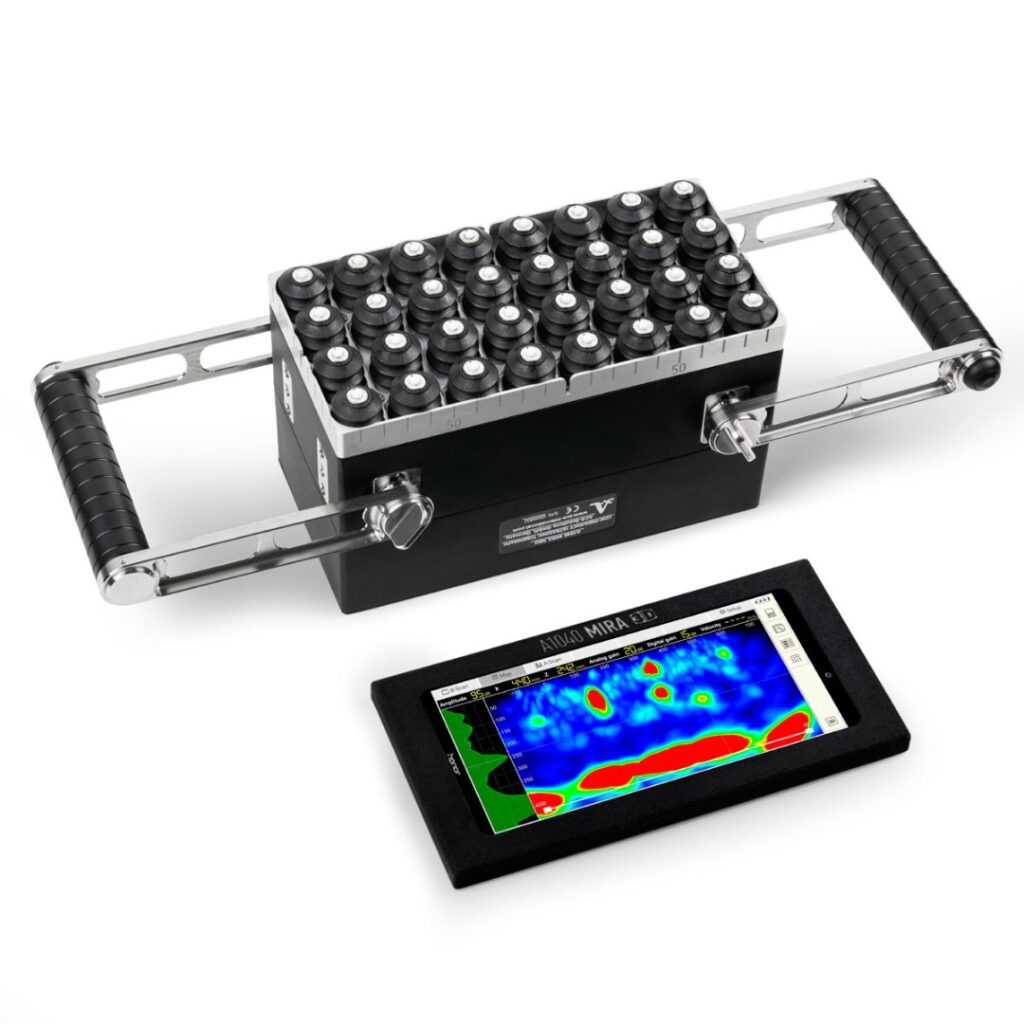

Shearwave tomography for concrete evaluation offers a range of applications, providing 3D visualization for accurate and detailed assessments. Here are some key applications:

The Rebound Schmidt Hammer Test, following ASTM C805 standards, is a reliable and widely accepted method for evaluating the strength and quality of concrete structures. It enables efficient and cost-effective assessments, assisting in decision-making, maintenance planning, and ensuring the long-term durability of concrete elements. At Accu-Test, we are dedicated to providing accurate and efficient assessments of In-place strength of concrete strength. Our skilled team of experts utilizes rebound Schmidt hammer testing techniques per ASTM C805 to evaluate the quality and integrity of concrete structures. By measuring the rebound velocity of a hammer impacting the concrete surface, we can determine its strength and assess potential variations across different areas.

This non-destructive testing approach allows us to quickly evaluate the condition of concrete in a cost-effective manner. With our Rebound Schmidt Hammer Test service, you can make informed decisions regarding construction, maintenance, and rehabilitation projects.

The Rebound Schmidt Hammer Test, following ASTM C805 guidelines, offers a range of valuable applications for concrete evaluation. Here are some key applications:

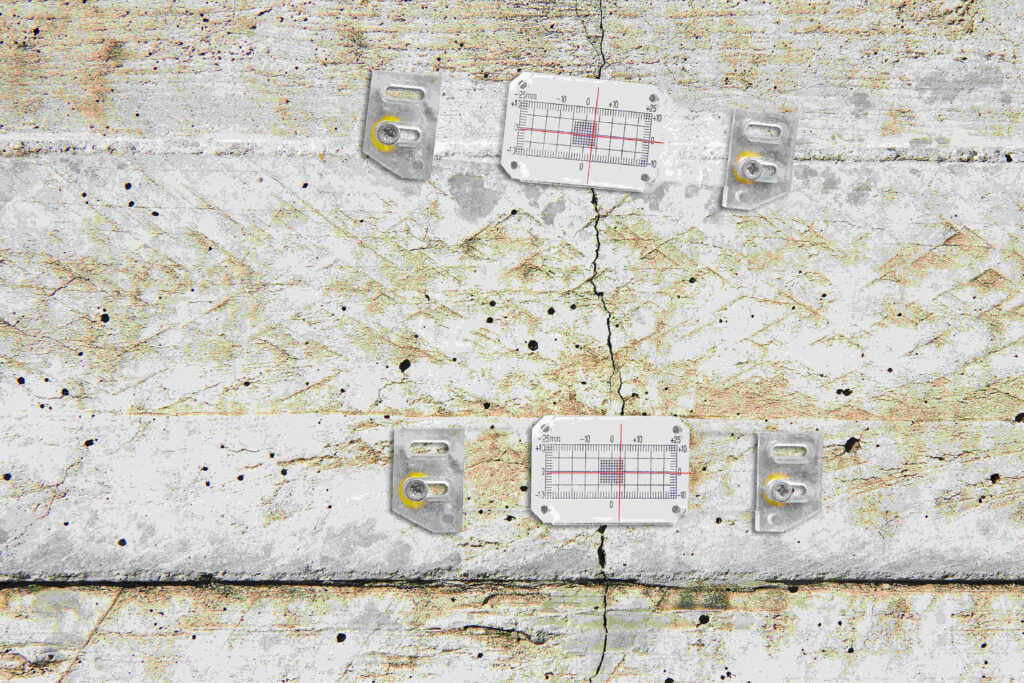

At Accu-Test, we understand the importance of early detection and monitoring of concrete cracks for maintaining the integrity of your structures. Our expert team utilizes advanced crack monitoring gauges to provide accurate and reliable assessments of crack behavior over time. By installing precision gauges along the crack lines, we can measure and monitor any changes in width, length, and movement, providing valuable insights into the structural health of your concrete elements.

Our non-destructive approach allows for continuous monitoring without causing further damage. With our Concrete Crack Monitoring service, you can proactively identify potential issues, make informed decisions regarding repairs or reinforcements, and ensure the long-term durability of your concrete structures. Concrete crack monitoring gauges offer a range of applications for effective monitoring of cracks in concrete structures. Here are some key applications:

Our team of experts at Accu-Test leverages Impact Echo method to provide accurate and comprehensive assessments of concrete structures. Impact Echo offers a non-destructive and non-invasive solution to evaluate critical properties of concrete, including thickness, density, and integrity. By harnessing sound waves and analyzing their reflections, we uncover invaluable insights into the quality and condition of your concrete elements. Whether you require assessments for construction projects, maintenance planning, or structural integrity verification, our Impact Echo service line ensures reliable and efficient evaluations, enabling you to make informed decisions and maximize the lifespan of your concrete structures.

By utilizing the Impact Echo method, our service line offers a comprehensive evaluation of concrete properties, enabling you to make informed decisions about maintenance, repair, and construction activities. Here are some key applications:

Our team of experts leverages Ground Penetrating Radar (GPR) method to provide accurate and detailed assessments of concrete structures. GPR offers a non-destructive and non-invasive solution to evaluate critical aspects of concrete, including detecting rebar, assessing concrete thickness, identifying voids, and locating potential anomalies within the structure. By sending electromagnetic waves into the concrete and analyzing the reflections, we uncover invaluable insights into the condition and integrity of your concrete elements. Whether you require assessments for construction projects, infrastructure maintenance, or structural investigations, our GPR service line ensures precise and efficient evaluations, empowering you to make informed decisions and optimize the performance of your concrete structures.

By leveraging the power of GPR technology, our service line provides accurate and reliable rebar scanning services, enabling you to make informed decisions, ensure structural integrity, and meet regulatory requirements. Here are some key applications: